For U.S. automotive manufacturers and suppliers relying on high-volume shipments from Mexico, efficiency is everything. However, the traditional RFP process used to contract transportation and distribution often fails to account for the fragmented nature of cross-border logistics—leading to unnecessary costs, delays and operational misalignment.

Here’s why:

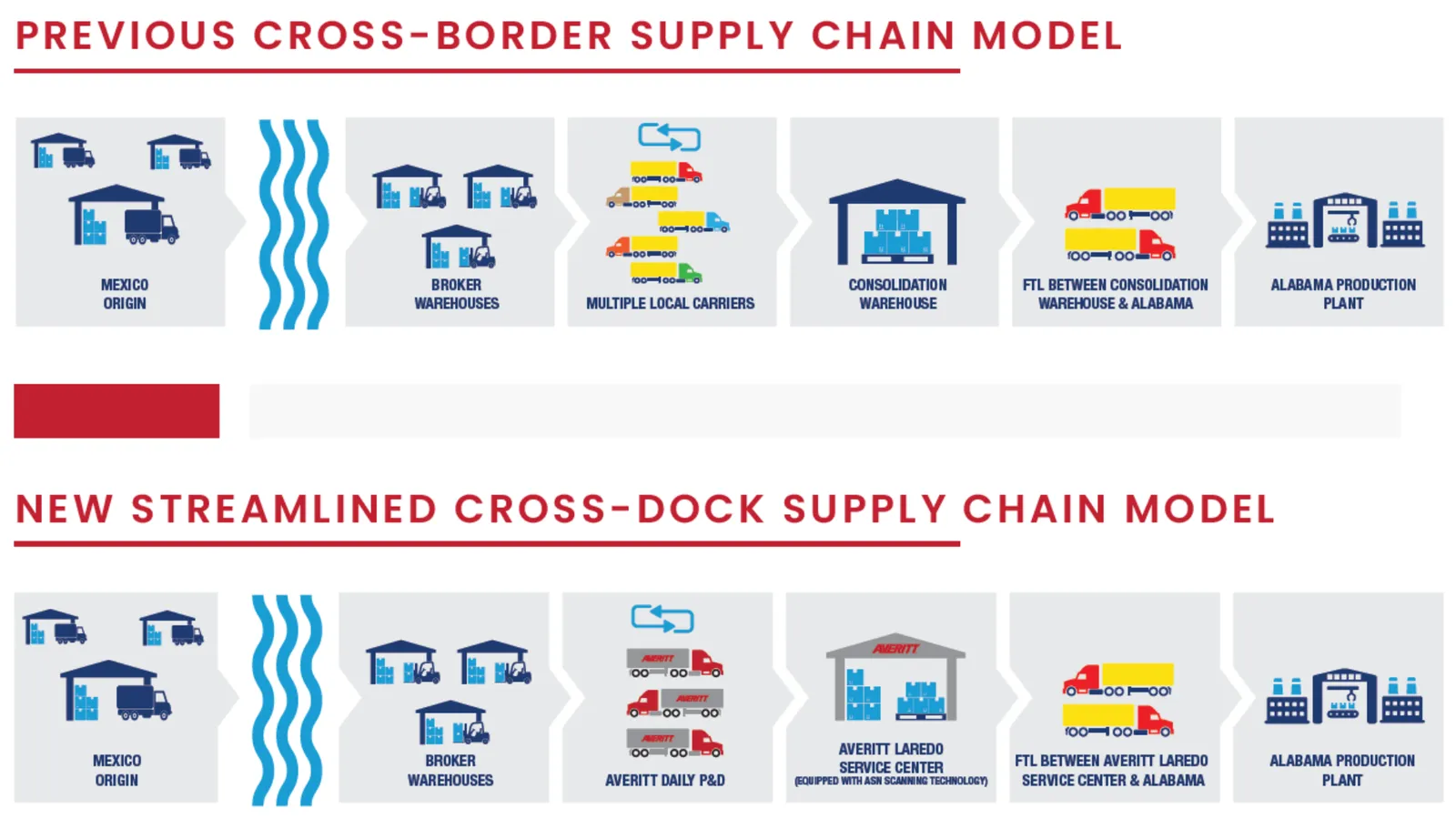

Many U.S.-based manufacturers and suppliers don’t control the transportation choices of their Mexico-based suppliers. Instead, suppliers ship independently to multiple freight broker warehouses along the U.S. side of the border—Laredo being a primary hub. As a result, manufacturers must then consolidate their freight from upwards of dozens of different broker warehouses, creating a logistical challenge.

The traditional RFP model seeks to solve this issue by contracting a logistics solutions provider to coordinate the local consolidation and full truckload shipping into the interior of the U.S. However, this approach adds unnecessary complexity and misalignment, particularly when the service provider lacks direct trucking assets.

Where the Traditional Model Falls Short

When a non-asset-based provider is awarded the contract, they rely on multiple local trucking companies to pick up freight from various broker warehouses and transport it back to a centralized warehouse for consolidation.

This approach creates significant risks and inefficiencies:

-

Inconsistent pickup schedules – With multiple trucking companies involved, the supply chain is easily disrupted due to variability in service levels, driver availability and capacity constraints.

-

Poor coordination between providers – When different trucking companies handle pickups and deliveries independently, misalignment in transit schedules can lead to delays and inefficiencies.

-

Limited visibility and tracking – Freight often moves without integrated ASN scanning, making it difficult to maintain real-time inventory accuracy and shipment predictability.

Ultimately, the misalignment between multiple trucking providers creates bottlenecks, unnecessary warehouse storage costs and slower delivery timelines—all of which negatively impact U.S. manufacturers trying to streamline their supply chains.

Rethinking The Strategy: A Fully Integrated, Asset-Based Approach

For one major automotive manufacturer in the U.S., Averitt takes a different, more streamlined approach to cross-border freight consolidation—one that eliminates fragmentation and ensures fluid, predictable movement from Laredo to its production plants.

Here’s how it works:

-

Averitt’s local LTL drivers operate consistent daily routes to pick up freight from multiple broker warehouses in Laredo.

-

All shipments move through Averitt’s Laredo service center, where they are scanned in using ASN data for real-time tracking.

-

Freight is consolidated efficiently into full truckloads at our facility—ensuring faster, more coordinated movement.

-

Deliveries move on Averitt’s asset-based truckload network or the manufacturer’s preferred carrier for seamless transport to U.S. plants.

With this approach, there is no reliance on multiple trucking providers, eliminating the risks of misaligned pickup schedules, disconnected tracking systems and inconsistent service quality.

The Results: A More Efficient Cross-Border Model

By leveraging Averitt’s fully integrated network, U.S. manufacturers and suppliers benefit from:

- A single, predictable carrier handling every step of the journey.

- Improved visibility with ASN scanning and real-time tracking.

- Reduced warehouse dwell times and supply chain bottlenecks.

- Lower transportation costs with streamlined, consolidated shipping.

- Scalability to adjust to fluctuating production demands.

Instead of relying on a patchwork of trucking providers, Averitt’s asset-based model keeps shipments moving efficiently and predictably.

The Future of Automotive Supply Chains: A Smarter Way Forward

As nearshoring to Mexico increases, U.S. manufacturers need a better cross-border logistics model—one that eliminates unnecessary handoffs, reduces costs and keeps supply chains running smoothly.

To see learn more about how this leading automotive manufacturer leveraged Averitt’s integrated approach to streamline cross-border shipments, read the full case study here.

For more information on how Averitt’s asset-based transportation solutions can help you optimize your Mexico-to-U.S. distribution, learn more here.