Dive Brief:

- BMW Group has successfully completed a pilot of deploying humanoid robots at its Spartanburg factory in South Carolina, the automaker announced in a press release Aug. 6.

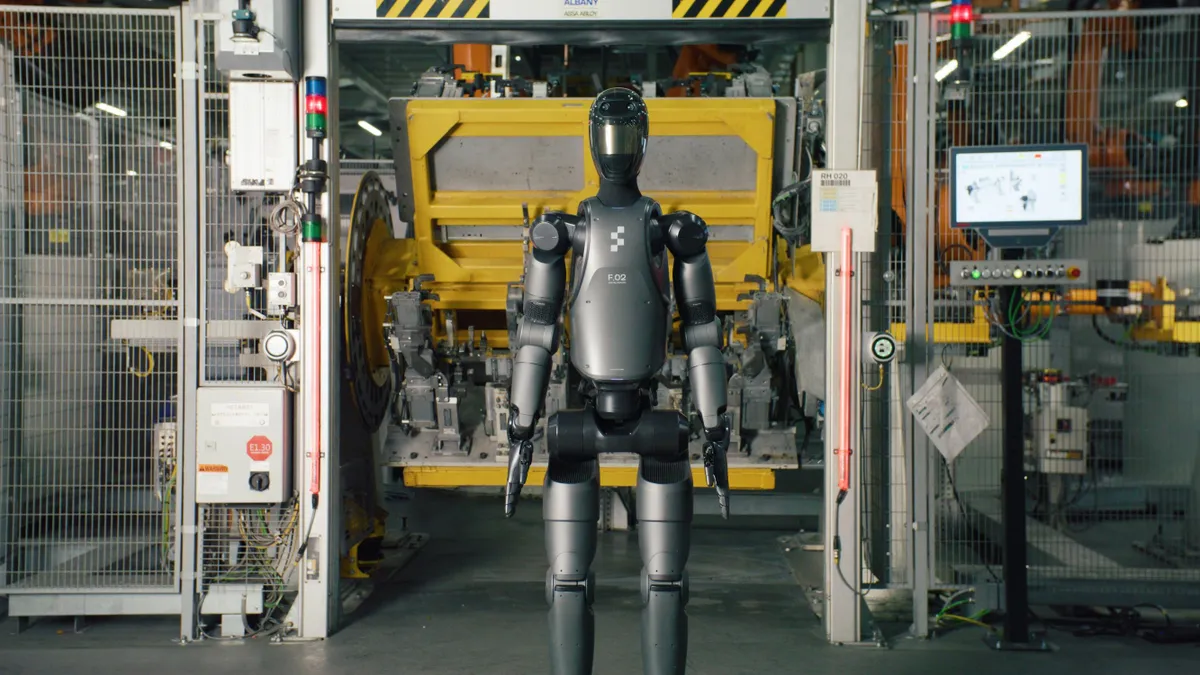

- The pilot began earlier this year with California-based robotics company Figure, which designed its robots to perform hazardous, repetitive or physically demanding jobs. The robots may one day work alongside humans on BMW’s vehicle assembly lines.

- “The developments in the field of robotics are very promising. With an early test operation, we are now determining possible applications for humanoid robots in production, said Milan Nedeljković, member of the board of management for production at BMW.

Dive Insight:

The use of robots could improve safety in automotive manufacturing operations, as well as in other industries. Figure’s robots are capable of advanced dexterity, which makes them well-suited for unsafe or repetitive tasks that could lead to work-related injuries on the assembly line.

The AI-powered robots can open doors, use tools, climb stairs, lift boxes and perform other tasks, according to Figure. The robot even has the ability to place complex parts in position with millimeter-level accuracy, according to BMW.

Figure’s latest robot has 3x the processing power of its predecessor, including better voice communication, improved cameras and microphones, as well as a high-performance battery. It features robotic “hands” that offer human-equivalent strength, according to the company.

“Figure 02 has significant technical advancements, which enable the robot to perform a wide range of complex tasks fully autonomously,” said Brett Adcock, founder and CEO of Figure, in the press release.

Despite the successful pilot, BMW says there are currently no Figure AI robots deployed at its Spartanburg plant, or a timetable to introduce them. In the interim, BMW will continue to work with Figure on collecting data and training capabilities for the Figure 02 robot for future use cases.

Other automakers are also exploring the use of robots at their manufacturing facilities.

General Motors has worked with its longtime partner Fanuc to develop robotics solutions to reduce the strain on workers and improve efficiency at its vehicle assembly plants. Meanwhile, during Tesla’s Q2 earnings call last month, CEO Elon Musk floated the idea of deploying thousands of its “Optimus” robots “doing useful things” within its production facilities by the end of next year.

In March, Mercedes-Benz and robotics company Apptronik announced an agreement to deploy humanoid robots in its manufacturing facilities. The two companies are also exploring potential use cases for robots, such as delivering parts to assembly line workers.